- Financing/Leasing Available | Se Habla Español

- +17137485441

- +17137485453

How to Choose the Best Laboratory Sample Pulverizer?

Choosing the right laboratory sample pulverizer is essential for accurate results. A good pulverizer ensures that samples are processed efficiently and uniformly. In various industries, including pharmaceuticals and materials testing, the need for precise sample preparation cannot be overstated.

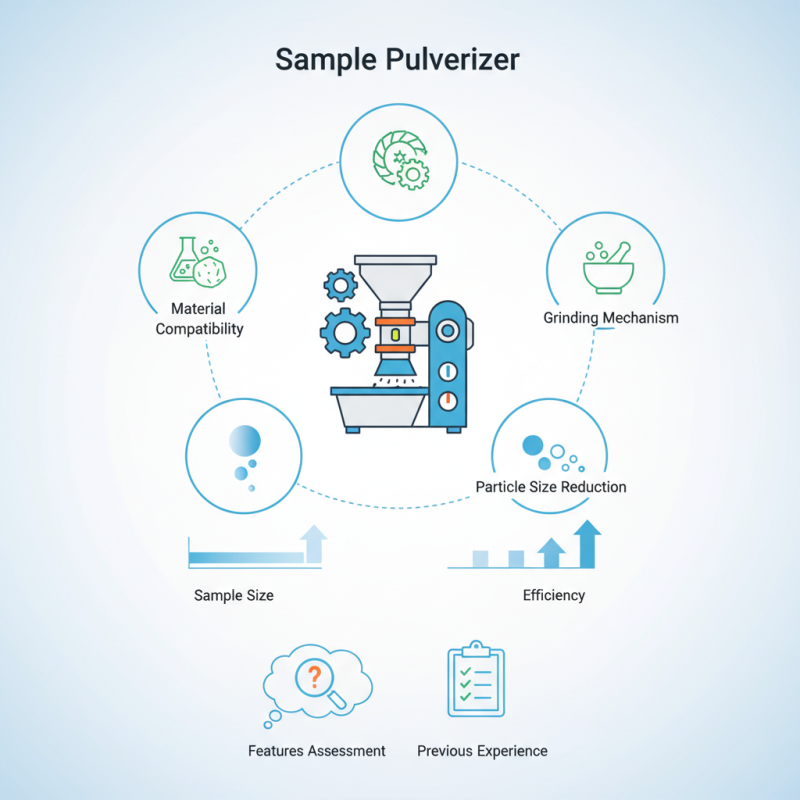

When selecting a laboratory sample pulverizer, consider factors such as material compatibility, grinding mechanism, and particle size reduction. The size of the sample being processed also plays a significant role. A machine that fits your specific requirements will enhance the efficiency of your lab operations.

However, many users overlook critical aspects, leading to suboptimal performance. It's important to assess the features each model offers. Are they adequate for your needs? Reflecting on previous experiences with laboratory sample pulverizers may guide your decision-making. Ultimately, the choice of pulverizer can greatly impact the results of your experiments. Thus, careful thought and research are necessary for success.

Understanding the Purpose of Laboratory Sample Pulverizers

Laboratory sample pulverizers play a crucial role in sample preparation. They reduce material to a fine powder, which is essential for accurate analysis. The choice of pulverizer affects the quality of results. Depending on the material, some pulverizers will perform better than others. For instance, a study by Materials Science highlights that particle size is critical for many applications. A finer grind often leads to better extraction rates in chemical analysis.

Different types of pulverizers include hammer mills, ball mills, and blade mills. Each type has its strengths. Hammer mills are versatile, suitable for tougher materials. Ball mills are often preferred for uniformity, especially in mineralogical studies. However, a report from the American Society for Testing and Materials shows that improper selection can lead to sample contamination. This becomes a significant issue in sensitive analytical procedures.

The specifications should align closely with the intended use. Many researchers overlook the importance of materials used in construction. A metallic contaminant from the pulverizer can skew results. Furthermore, the energy consumption and noise levels also matter. These factors can hinder operations in smaller labs. A solid understanding of your needs is essential. Would a versatile machine meet the demands, or is a specialized one necessary? Choosing the right pulverizer requires careful consideration and reflection.

Comparison of Laboratory Sample Pulverizer Types

Factors to Consider When Choosing a Pulverizer

When choosing a laboratory sample pulverizer, several factors come into play. The material type is crucial. Different materials require specific grinding techniques. For example, hard samples might need high-impact forces. Soft samples, on the other hand, can be processed with less intensive methods. Understanding this requirement can save time and enhance efficiency.

Particle size is another important consideration. You should know the desired final particle size before making a decision. Some pulverizers provide adjustable settings for this. Others may not. Testing a sample run might reveal limitations. If you have a specific size in mind, ensure the pulverizer can achieve it. Pay attention to the capacity of the machine as well. A small lab may not need a high-capacity model. However, larger operations might require more power and throughput.

Finally, maintenance should not be overlooked. Some machines require frequent cleaning and calibration. This can lead to downtime. Explore user reviews and experiences. What challenges do users face? It can provide insight into reliability and performance. Finding a balance between features and practicality can be challenging. Each lab's needs differ, making it important to analyze these factors carefully.

Types of Laboratory Sample Pulverizers and Their Applications

Choosing the right laboratory sample pulverizer is crucial for effective sample preparation. There are different types of pulverizers, each suited for specific applications. Hammer mills are common for coarse grinding. They work quickly and effectively, but may generate heat, affecting sensitive samples.

Ball mills are another option. They provide fine particle size reduction, ideal for precise applications. However, they can be slow and require regular maintenance. The choice depends on the material being processed. For brittle materials, a cryogenic mill may be necessary. These mills freeze samples before grinding, preserving their molecular structure.

Laboratory sample pulverizers also vary in size and capacity. Small benchtop models are handy for limited sample sizes. Larger, industrial-grade pulverizers handle large volumes but may require significant space. Reflecting on your needs can clarify what type to choose. Remember, the best pulverizer isn’t always the most expensive. Find a balance between cost, function, and your specific requirements for optimal results.

Evaluating Performance and Efficiency of Pulverizers

When selecting a laboratory sample pulverizer, evaluating performance and efficiency is crucial. A pulverizer's speed matters. Faster models often produce finer samples, but speed may compromise sample integrity. Careful consideration is needed here.

Assessing energy consumption is also important. Some pulverizers consume more energy than others. High energy use can inflate operational costs. This could lead to budget constraints. Be mindful of the power efficiency ratings provided by manufacturers. They often indicate how much energy is needed for various materials.

Material compatibility should not be overlooked. Different pulverizers handle various sample types differently. Some models excel with hard samples, while others may struggle. Testing with smaller quantities can reveal potential issues. It might create unexpected results.

Regular maintenance is another factor. Neglect can lead to decreased performance over time. Observing how a pulverizer performs with regular use is essential to maintain efficiency.

Maintenance and Care for Laboratory Sample Pulverizers

When maintaining laboratory sample pulverizers, attention to detail is crucial. Regular inspection helps identify wear and tear. Small cracks or unusual noises can signal deeper issues. Keep an eye on the blades; they should remain sharp for optimal performance.

Tips for maintenance: Always clean the pulverizer after use. Remove residue to prevent contamination. Lubricate moving parts periodically. This can extend the life of your equipment. If parts become loose, re-tightening them can prevent costly repairs.

Sometimes, users overlook misalignments. Even minor misalignments can create stress on components. This can lead to breakdowns, which disrupt productivity. Regular adjustments can help minimize these risks. Keep a maintenance log to track issues and repairs. It encourages proactive care rather than reactive fixes.