- Financing/Leasing Available | Se Habla Español

- +17137485441

- +17137485453

2026 Best Thermal Paper Roll Manufacturer Options Available?

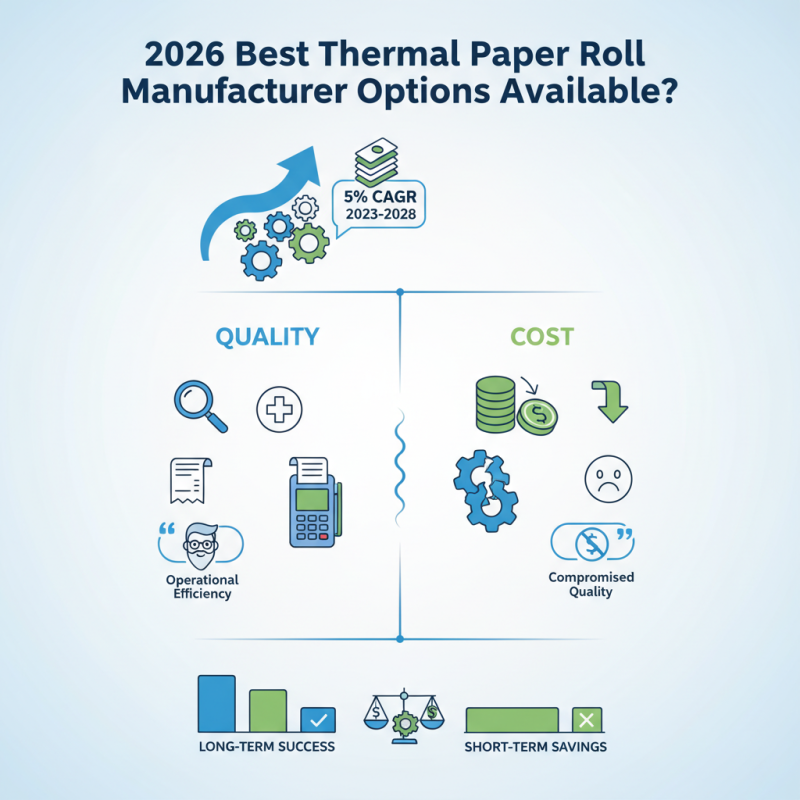

In the rapidly evolving landscape of printing solutions, choosing a reliable thermal paper roll manufacturer is crucial. The thermal paper market is anticipated to grow at a 5% CAGR from 2023 to 2028, according to recent industry insights. As businesses adopt more efficient technologies, quality in thermal paper production becomes essential.

Johnathan Lewis, a noted expert in the thermal paper industry, states, "The choice of a thermal paper manufacturer can dramatically affect a company’s operational efficiency." His words emphasize the pivotal role these manufacturers play in supporting diverse sectors. With varied applications, from point-of-sale systems to medical devices, the demand for high-quality thermal rolls is increasing.

Yet, not all manufacturers meet the same standards. Some companies focus solely on cost, compromising quality. This inconsistency leads to operational challenges and customer dissatisfaction. Therefore, thorough research is vital for businesses seeking dependable thermal paper solutions. Balancing quality and cost is not straightforward, but it's essential for long-term success.

Understanding Thermal Paper Rolls and Their Uses

Thermal paper rolls are essential in various sectors, notably retail and banking. These rolls contain a special coating that turns dark when exposed to heat. Their efficiency is evident in receipts, tickets, and labels. In 2020, the global thermal paper market was valued at over $3 billion, showcasing their significant role in daily transactions.

Many businesses rely on thermal paper for quick transactions. The market is expected to grow by 5.2% annually until 2027. However, not all thermal papers are the same. Variability in quality can affect print durability and clarity. Poor-quality rolls may lead to faded prints and customer dissatisfaction. For example, a retailer using subpar thermal paper might find its receipts unreadable after a few months.

Environmental concerns also arise with thermal papers. The bisphenol A (BPA) that some papers contain poses health risks. Many companies are now opting for BPA-free thermal papers. Yet, these alternatives may also come with trade-offs. They can be more expensive and may not perform as well under all conditions. Balancing quality, cost, and safety is a challenge for many businesses today.

2026 Best Thermal Paper Roll Manufacturer Options Available

| Manufacturer Location | Roll Size (mm) | Paper Weight (g/m²) | Core Size (mm) | Use Cases |

|---|---|---|---|---|

| North America | 80 x 80 | 55 | 12 | POS Systems, ATM Receipts |

| Europe | 57 x 40 | 65 | 12 | Shipping Labels, Retail |

| Asia | 80 x 50 | 70 | 25 | Inventory Management, Ticketing |

| Australia | 80 x 120 | 60 | 25 | Healthcare, Receipts |

| South America | 58 x 60 | 50 | 12 | Food & Beverage, Gas Stations |

Factors to Consider When Choosing a Thermal Paper Roll Manufacturer

When selecting a thermal paper roll manufacturer, several factors come into play. Quality is paramount. Not all manufacturers use the same materials. Look for those that prioritize durable paper. Cheaper options might save money now but can lead to issues later.

Another important factor is consistency. A reliable manufacturer should provide uniform rolls. This ensures your printing processes run smoothly. Variations can cause jams, wasting time and resources. Consider customer service as well.

Good support can resolve issues swiftly. Sometimes delays happen, and open communication helps. Evaluate the manufacturer’s reputation through reviews. This offers insight into their reliability. Seek feedback from other businesses. Each factor shapes the decision, so take time to reflect. The right choice today can impact your operations tomorrow.

Top Manufacturers of Thermal Paper Rolls in 2026

The thermal paper roll industry is evolving rapidly, with several key manufacturers leading the market in 2026. Recent reports indicate that the global thermal paper market is projected to reach $5 billion by 2026, showing a significant increase in demand. This growth is driven by the rising usage of thermal printing technology in various sectors, including retail and logistics.

Many manufacturers are focusing on sustainability. They are aiming to create eco-friendly thermal papers. According to statistics, around 40% of companies have begun using recycled materials in their production processes. It's essential to recognize that not all manufacturers follow these sustainable practices. Some still rely on conventional methods, raising questions about their environmental impact.

The competition among suppliers is fierce. Quality varies widely, and not every option meets industry standards. Inaccurate printing and fading issues can arise with lower-quality rolls. Reports suggest that about 25% of businesses experience problems with thermal paper quality. Organizations need to thoroughly evaluate their suppliers to ensure reliability and performance.

Evaluating Quality and Performance of Thermal Paper Products

When evaluating thermal paper products, quality and performance are key. Not all thermal paper rolls are created equal. Some papers fade quickly, while others maintain clarity for longer periods. The choice of base materials plays a significant role in durability and legibility. High-quality thermal paper should resist smudging and offer crisp print quality.

Price is not always an indicator of performance. Some budget options might perform well initially but deteriorate quickly. Users often report issues after a few weeks of use. Seek samples wherever possible. Testing is crucial before bulk purchases.

Another aspect to consider is the environmental impact. Many thermal papers rely on chemicals that may not be eco-friendly. It's worth exploring options that claim to be recyclable or made from sustainable sources. Feedback from previous users can guide decisions but be cautious. Reviews may not always reflect true performance. High satisfaction rates do not guarantee the same experience for everyone. Balancing quality, cost, and sustainability requires careful consideration.

Future Trends in Thermal Paper Roll Manufacturing

As thermal paper roll manufacturing evolves, several trends stand out. The shift towards eco-friendly materials is gaining momentum. Manufacturers are increasingly focusing on sustainable paper sources. This change aims to reduce environmental impact. More businesses seek recycled options, promoting a circular economy. These materials, however, can sometimes compromise print quality. Balancing sustainability with performance remains a challenge.

Innovation in technology also plays a significant role. Digital printing techniques are emerging, allowing for more precise designs. Manufacturers experiment with heat-sensitive coatings to enhance longevity. However, high production costs may limit adoption. Companies are exploring automation to streamline processes. While efficiency increases, it often raises concerns about job displacement. Finding harmony between innovation and workforce stability is vital.

Consumer preferences are shifting as well. Demand for high-quality prints is rising. Businesses want vibrant colors and sharp images. Yet, preferences fluctuate due to trends and technology changes. Being adaptable is crucial in this landscape. Manufacturers need to anticipate shifts rather than just react. It’s a dynamic field that requires constant reflection and adjustment. Balancing quality, sustainability, and innovation will shape the future.