- Financing/Leasing Available | Se Habla Español

- +17137485441

- +17137485453

Top 10 Best Commercial Bakery Equipment for Your Bakery?

In the competitive world of baking, the right commercial bakery equipment can make all the difference. A recent industry report by IBISWorld indicates that the commercial bakery equipment market is projected to grow at a compound annual growth rate of 3.5% over the next five years. This growth reflects the increasing demand for high-quality baked goods. To meet consumer expectations, bakeries must invest in efficient and innovative equipment.

According to expert John Smith, a leading analyst in the commercial bakery equipment sector, "Investing in quality equipment not only improves production but also enhances product quality." Yet, many bakers overlook the importance of proper maintenance. Equipment that is not regularly serviced can lead to unexpected breakdowns and lost revenue.

As bakeries strive to stand out, choosing the best equipment is paramount. From ovens that ensure even baking to mixers that improve dough consistency, selecting the right tools can be the key to success. However, the variety of options available can be overwhelming, leading to potential mistakes. Embracing both innovation and proven methods is essential while navigating this complex landscape.

Top Commercial Bakery Equipment: An Overview of Essential Tools

When setting up a bakery, selecting the right commercial bakery equipment is crucial. Essential tools streamline operations and enhance productivity. According to industry reports, nearly 75% of bakeries find that high-quality equipment directly impacts their efficiency. A dough mixer, for example, can save hours of manual labor. It handles large batches and ensures consistent mixing, which is vital for quality.

Another critical piece of equipment is a commercial oven. Many bakeries struggle with uneven baking, leading to dissatisfied customers. A reliable oven offers precise temperature control. Interestingly, around 60% of bakers identify baking quality as their top priority. Investing in a multi-deck oven can maximize output.

Additionally, refrigeration is often overlooked but essential. Maintaining ingredient freshness is vital. Reports indicate that poor storage can lead to 20% more waste in inventory. Thus, commercial refrigerators must be ample and efficient. Selecting the right equipment can seem overwhelming. It's a challenge that requires careful consideration and reflection on what truly benefits the business. Each tool carries its responsibilities and potential for improvement.

Understanding the Importance of Quality Bakery Equipment for Production

Quality bakery equipment plays a critical role in production efficiency and product consistency. A recent report from the American Bakers Association highlights that nearly 40% of bakeries reported an increase in production speed by upgrading their equipment. This statistic underscores the importance of investing in reliable tools for baking, mixing, and packaging.

When a bakery is equipped with the right machinery, it can reduce manual labor. This not only helps in saving time but also minimizes errors in production. For example, dough mixers can ensure a consistent texture, leading to better product quality. Investing in high-quality ovens can also decrease baking times while improving energy efficiency. However, it's essential to balance quality and cost.

**Tips:** Regular maintenance of equipment is crucial. Without it, performance can decline. Scheduling periodic check-ups can prevent major breakdowns. Consider employee training on equipment usage to maximize efficiency.

The challenge for many bakeries is understanding which equipment is worth the investment. Not every bakery needs the latest technology. Reflecting on what equipment aligns with production goals is vital. Assessing daily needs versus potential growth can help prioritize purchases. This process can lead to better financial decisions for the business.

Top 10 Best Commercial Bakery Equipment for Your Bakery

This chart displays the importance rating of various bakery equipment in a commercial setting. The ratings reflect how critical each piece of equipment is to the successful operation of a bakery, with a scale from 1 to 10, where 10 indicates the highest level of importance.

Key Features to Look for in Bakery Ovens and Mixers

When selecting bakery ovens, consider efficiency and even heat distribution. An oven with multiple settings allows versatility in baking various goods. Look for features like steam injection. This helps create a perfect crust for breads. An adjustable temperature range is essential for different recipes. Some ovens may lack precise temperature control, leading to inconsistent results.

In mixers, power and speed options are crucial. A high-speed setting can whip cream quickly. Ensure the mixer has multiple attachments for versatility. A spiral dough mixer is beneficial for heavy bread dough. However, not all mixers handle large batches well, which can be a problem during peak times.

Cleanliness should be a priority too. Equipment that is easy to clean helps maintain hygiene standards. Durable materials should withstand daily use. Think about space; your layout matters. Some equipment requires more room than expected, which can lead to cluttered workspaces. This might slow down production and impact efficiency.

Top 10 Best Commercial Bakery Equipment for Your Bakery

| Equipment Type | Key Features | Capacity | Energy Efficiency | Price Range |

|---|---|---|---|---|

| Convection Oven | Even heat distribution, multiple racks | Up to 10 trays | High | $3,000 - $10,000 |

| Deck Oven | Stone baking surface, steam injection | Up to 6 trays | Medium | $5,000 - $15,000 |

| Spiral Mixer | Heavy-duty design, variable speed | Up to 220 lbs dough | High | $2,000 - $8,000 |

| Planetary Mixer | Multiple attachments, versatile use | Up to 80 quarts | Medium | $1,500 - $5,000 |

| Proofing Cabinet | Controlled humidity and temperature | 30-40 trays | High | $3,000 - $12,000 |

| Dough Sheeter | Adjustable thickness, easy-to-use | Up to 30 inches | Medium | $1,500 - $4,000 |

| Blast Chiller | Rapid cooling, preserves quality | Up to 10 pans | High | $3,500 - $15,000 |

| Baking Sheet Pan | Durable, non-stick surface | Standard sizes available | N/A | $10 - $50 |

| Dough Divider | Precision cuts, consistency | Up to 30 lbs dough | Medium | $1,000 - $3,000 |

The Role of Refrigeration Systems in Maintaining Bakery Quality

Refrigeration systems are crucial for preserving the quality of baked goods. They help maintain the texture and flavor of products. A well-functioning refrigerator prolongs the shelf life of ingredients. Freshness is key in the bakery business. Customers expect the best.

Proper temperature control can be challenging. Too cold can dry out dough; too warm can lead to spoilage. Balancing temperature is essential for yeast and cream-based items. Investing in a reliable refrigeration system is important. Regular maintenance helps avoid unexpected breakdowns.

Many bakers overlook the need for backup systems. A sudden failure can mean losing a day's work. This oversight can hurt business. Backup solutions provide peace of mind. Understanding these systems can improve overall quality. Investing time in knowledge can make a significant difference.

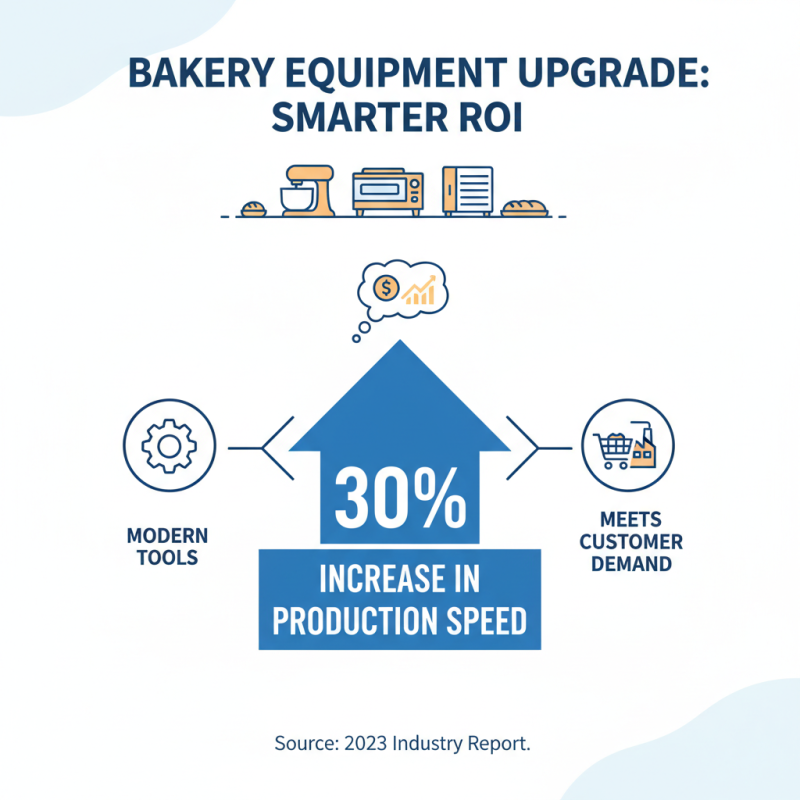

Evaluating Return on Investment for Bakery Equipment Purchases

When assessing bakery equipment purchases, return on investment (ROI) is critical. Many bakeries see a significant uptick in efficiency with modern tools. According to a 2023 industry report, bakeries that upgraded their equipment experienced a 30% increase in production speed. This not only enhances output but also meets rising customer demand efficiently.

Comparing initial costs against long-term savings is essential. For instance, energy-efficient ovens may require a higher upfront investment. However, they can lower energy costs by up to 25% annually. More efficient mixers can cut down ingredient processing times, thus reducing labor costs. Yet, these benefits are not immediate; they require careful planning and execution.

Bakeries also need to consider maintenance costs. Over time, outdated machines can incur hidden costs. Data shows that 40% of small businesses experience production delays due to equipment failures. Investing in newer, reliable systems can minimize such risks. Reflecting on these factors can lead to smarter purchases that ultimately maximize profits in the long run.

Related Posts

-

2025's Top 5 Baking Ovens for Home: The Ultimate Guide to Perfect Pastries

-

How to Choose the Best Stainless Steel Electric Oven for Your Kitchen

-

Top Commercial Deck Oven Features and Benefits for Your Bakery Business?

-

2025 Top Commercial Rack Oven Features and Benefits You Need to Know

-

Top 10 Best Baking Ovens for Home Use: Ultimate Guide for Every Baker

-

Why You Should Consider a Wood Burning Oven for Your Cooking Needs