- Financing/Leasing Available | Se Habla Español

- +17137485441

- +17137485453

2026 Best Hydraulic Hose for Sale Options and Buying Guide?

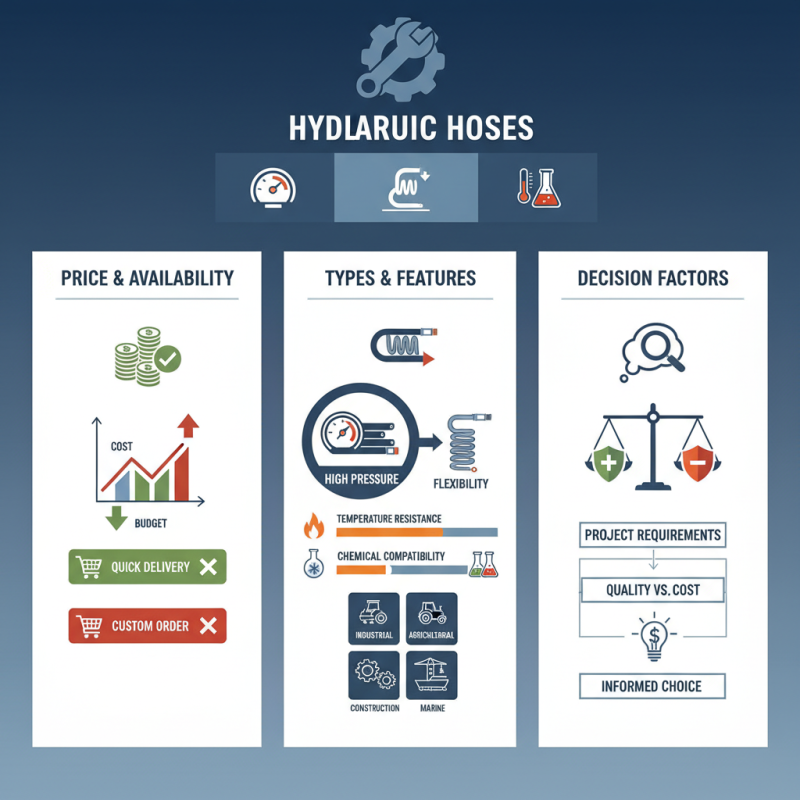

When searching for the best hydraulic hose for sale, variety can be overwhelming. Many brands claim their products are the best. However, the right choice depends on specific needs. Quality matters, but so do price and availability.

In 2026, different types of hydraulic hoses are available. Some are designed for high pressure, while others focus on flexibility. Features like temperature resistance and chemical compatibility are key. Understanding these details can make a significant difference.

Buying the right hydraulic hose for sale requires careful consideration. Reflect on your project requirements. A less expensive option might save money, but could lead to performance issues. Weighing pros and cons will help you make an informed decision.

2026 Overview of Hydraulic Hoses: Key Features and Benefits

Hydraulic hoses are critical components in many industrial applications. They transmit hydraulic fluid and provide controlled movement in machinery. Engineers have found that the right hose can significantly affect the system's efficiency. According to a recent industry report, over 40% of machinery failures stem from hose-related issues. This statistic highlights the importance of selecting high-quality hoses.

Key features to consider include pressure ratings and temperature resistance. Hoses must withstand various pressures, often exceeding 3,000 psi in heavy machinery. Additionally, temperature ranges can vary. Some hoses can operate in conditions as low as -40°F and as high as 250°F. Choosing a hose that meets these specifications is not always straightforward. Improper selection can lead to leaks or failures.

Benefits include improved performance and durability. High-quality hydraulic hoses offer excellent flexibility and resistance to abrasion. This results in longer service life and reduced maintenance costs. However, sourcing these hoses can be challenging. Availability may vary, and not all suppliers provide accurate information about their products. Ensuring that you have a reliable supplier is crucial for optimal performance.

Types of Hydraulic Hoses: Choosing the Right One for Your Needs

When selecting hydraulic hoses, understanding their types is crucial. There are primarily three categories: rubber, thermoplastic, and metal hoses. Each type serves different functions. Rubber hoses are flexible and durable, suited for various pressures. Thermoplastic options are lightweight and resistant to chemicals. Metal hoses handle extreme temperatures and pressures effectively.

Tips: Consider your specific application. Assess the environment where the hose will be used. Is it exposed to heat or chemicals? This impacts your selection.

Buying the right hydraulic hose isn't just about picking one that looks good. It's about functionality and safety. Pay attention to the hose's pressure rating. A mismatched hose can lead to failures, risking accidents. Look for hoses that offer a burst pressure significantly higher than your system's working pressure.

Tips: Always double-check compatibility with your existing equipment. Misalignment can cause leaks or even damage. Don’t overlook the importance of testing your system after installation. A simple oversight can lead to costly repairs.

Top Brands for Hydraulic Hoses: A Comparative Analysis

When selecting hydraulic hoses, comparing brands is essential. Different manufacturers offer unique features that can affect performance. Some brands prioritize durability, while others focus on flexibility. Consider the application and environment when choosing a hose. Look at the material construction. This can impact longevity and serviceability.

Tips: Always check for certifications. This ensures the hose meets industry standards. Additionally, consider the temperature and pressure ratings. These factors are critical for safety. Use different hoses for varying applications to avoid damage.

Be wary of flashy marketing claims. Sometimes, the actual performance does not match the promise. Reading customer reviews can provide insights into real-life experiences. Understand that not every hose is ideal for every task. Testing a few options may help in finding the right fit. Make a list of must-have features and refer back to it when shopping.

Buying Considerations: Factors to Evaluate Before Purchase

When purchasing hydraulic hoses, certain key factors are essential for making informed decisions. Material quality stands out. Hoses made from synthetic rubber often outperform others in durability and heat resistance. According to industry reports, 65% of hose failures are due to material fatigue. Evaluating the abrasion resistance and flexibility of hoses can drastically improve longevity and efficiency.

Tips: Always check for hose ratings. They should match or exceed system pressures.

Another consideration is the size. Proper diameter selection is crucial for fluid flow and pressure loss. A mismatch can lead to decreased performance. Research indicates that a 10% increase in hose diameter can enhance flow rates significantly.

Tips: Consult technical specifications and guidelines. They provide valuable information on fitting and compatibility.

Where to Buy Hydraulic Hoses: Best Retailers and Online Options

When looking for hydraulic hoses, knowing where to buy them is crucial. Many people prefer local retailers. These stores usually allow you to inspect the hoses in person. However, stock can be limited. Sometimes, the options aren’t what you need. Browsing online can open up a world of choices beyond your local area. Websites often carry a wider range of products.

Online shopping also comes with its challenges. Shipping times can vary widely. Plus, determining the right size can be tricky without physical measurement. It's essential to read reviews and check ratings before purchasing. You may encounter some unexpected surprises when hoses arrive. Sometimes they don't match the specifications you thought they had. Make sure to measure your requirements accurately.

Don’t forget to consider customer service for both online and offline purchases. You might need help selecting the right hose type. Local retailers may offer better face-to-face assistance. Online stores may provide chat support. Both have their pros and cons. Take some time to research before finalizing a purchase. It can save you time and money in the long run.

2026 Best Hydraulic Hose for Sale Options and Buying Guide

| Features | Specifications | Price Range | Best For | Where to Buy |

|---|---|---|---|---|

| High Flexibility | 1/4" to 1" diameter, working pressure up to 4000 PSI | $15 - $30 per foot | Heavy machinery and mobile equipment | Online retailers, local hardware stores |

| Abrasion Resistant | 3/8" to 2" diameter, working pressure up to 5000 PSI | $20 - $40 per foot | Construction and mining applications | Specialty suppliers, online marketplaces |

| Temperature Resistant | 1/2" to 1" diameter, suitable for -40°F to 250°F | $18 - $35 per foot | Agricultural and industrial equipment | Local industrial suppliers, online retail |

| Chemical Resistance | 1/4" to 1" diameter, compatible with caustic fluids | $25 - $50 per foot | Chemical processing and transport | Chemical supply companies, online platforms |

| Low Temp Performance | 1/2" to 1" diameter, suitable for extreme cold | $22 - $45 per foot | Cold weather operations | Heavy equipment retailers, online shops |